PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Carbon H Beam

Carbon Steel Profiles mainly include H-beam, T-beam, Channel Steel, I-beam, Angle Steel, etc. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks, warehouses, metal components and factory frames, etc.

Category: Carbon H beam

Key word: Carbon H beam

![]() Whatsapp :+86 17563511135

Whatsapp :+86 17563511135

![]() Email : aimee@sdxtmetal.com

Email : aimee@sdxtmetal.com

Widely used in various metal structures, bridges, machinery manufacturing and shipbuilding, various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouses wait.

| Product Name | H beam |

|---|---|

| Size | 1.Web Width (H): 100-900mm |

| 2.Flange Width (B): 100-300mm | |

| 3. Web Thickness (t1): 5-30mm | |

| 4. Flange Thickness (t2): 5-30mm | |

| Length | 1m – 12m , or according to your requests. |

| Standard | GB ASTM, JIS, SUS, DIN, EN etc |

| Material | Q235B Q345B Q420C Q460C SS400 SS540 S235 S275 S355 A36 A572 G50 G60 |

| Technique | Hot rolled |

| Application | Construction structure |

| Price Item | FOB、CIF、DDU、FCA、EXW ,.etc |

| Packing | Export standard packing or according to customers’ requirement |

| Supply Ability | Within10-15 workdays,25-30days when the quantity beyond 1000tons |

Carbon H beam steel, recognized for its H-shaped cross-section, is a preferred material in various construction and engineering fields due to its structural efficiency and versatility. Here are some defining application characteristics of carbon H beam steel:

1. Structural Support and Foundation

- Applications: Building frameworks, bridges, warehouses, commercial and residential constructions.

- Explanation: Carbon H beams provide exceptional strength and stability, making them ideal for heavy load-bearing structures. Their unique shape offers superior resistance to bending and shear forces, essential for supporting the weight of large buildings and bridges.

2. Durability and Longevity

- Applications: Industrial facilities, offshore structures, and environments with corrosive elements.

- Explanation: Carbon steel, especially when treated or coated, exhibits high durability against environmental stresses, corrosion, and wear. This makes H beams suitable for long-term applications in challenging conditions, ensuring the longevity of the structures they support.

3. Design Flexibility

- Applications: Architectural designs, custom constructions, and interior frameworks.

- Explanation: The H beam’s shape allows architects and engineers to explore creative and innovative design possibilities. Its strong yet relatively lightweight nature enables the construction of complex and aesthetically pleasing structures without compromising on strength or safety.

4. Cost-Effectiveness

- Applications: Budget-sensitive projects in construction and infrastructure development.

- Explanation: Given their strength and durability, carbon H beams can be a cost-effective choice by reducing the need for frequent replacements or repairs. Their efficiency in material use and ease of assembly also contribute to overall cost savings.

5. Recyclability and Environmental Sustainability

- Applications: Green building projects and sustainable construction practices.

- Explanation: Steel is one of the most recyclable materials in the world. Carbon H beams can be repurposed or recycled at the end of their life cycle, reducing waste and supporting environmentally sustainable construction initiatives.

6. Resistance to Fire and Heat

- Applications: Fire-sensitive environments like power plants, refineries, and high-rise buildings.

- Explanation: Carbon H beam steel exhibits resilience to fire and heat, maintaining structural integrity at higher temperatures compared to other building materials. This property is crucial for fire safety in construction projects.

7. Seismic Resistance

- Applications: Earthquake-prone areas requiring structures with flexibility and resilience.

- Explanation: The flexibility and strong connection points of H beam structures offer better performance under seismic activity. This makes them a preferred choice in regions where earthquake resistance is a critical concern.

8. Ease of Construction and Assembly

- Applications: Projects with tight schedules and labor constraints.

- Explanation: Carbon H beams are relatively easy to assemble and can be prefabricated, allowing for quicker construction times and lower labor costs. Their standard sizes and shapes facilitate efficient transportation and handling.

Profile package and shipment

Carbon steel profile video

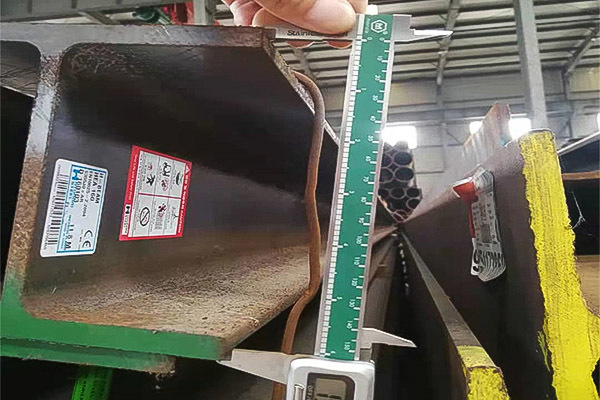

Carbon steel profile inspection

Produce-shipment-service

Modern factory

Professional production

single customize

plenty stockhouse

Delivery ontime

shipping support

prepare inspection

Global servise

Related products

FAQ

A What range of steel products does your factory produce?

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

B Are your steel products certified or graded, and how can I trust their quality?

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

CCan your factory handle bulk orders within short time frames?

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

D How does your company ensure the sustainability of production?

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

E What measures are in place to ensure the safety and welfare of workers in your factory?

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

F Do you offer customized steel solutions for specific industry needs?

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

G How do you handle logistics and transportation, and can customers track their orders?

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

H What is your policy on returns or defective products?

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.