PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Carbon I Beam

Widely used in various metal structures, bridges, machinery manufacturing and shipbuilding, various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouses wait.

Category: Stainless steel

Key word: Stainless steel pipe

![]() Whatsapp :+86 17563511135

Whatsapp :+86 17563511135

![]() Email : [email protected]

Email : [email protected]

Carbon I beam steel, often referred to simply as I beams, are long, steel members that are characterized by their I-shaped cross-section.

1.Industrial structure of the steel structure bearing bracket

2.Underground engineering steel pile and retaining structure

| ITEM | DESCRIPTION |

|---|---|

| Product | Carbon Steel I Beam |

| Standard | GB ASTM, JIS, SUS, DIN, etc |

| Grade | Q235,Q345,SS400,SS490,S235/S275,A36,A992,A572gr50 |

| Flange Width | 50-400mm |

| Flange Thickness | 8mm – 64mm |

| Web Width | 100mm~900mm |

| Web Thickness | Web Thickness |

| Product Category | Metallurgy, Mineral & Energy. |

| Technique | Hot rolled |

| Usage | Mechanical & Manufacture, Steel strcuture, Shipbuilding, Bridging, Automobile Chassis. |

The I beam is one of the most common types of structural steel used in construction and engineering because of its unique combination of strength, efficiency, and versatility. Here are some key application characteristics of carbon I beam steel:

1. High Strength-to-Weight Ratio

- I beams are designed to provide a high strength-to-weight ratio. This makes them ideal for various construction projects where durability and load-bearing capacity are essential, but without the added weight of solid steel sections. This characteristic is crucial for the structural integrity of buildings, bridges, and other structures, allowing them to withstand heavy loads and harsh conditions.

2. Versatility in Construction and Engineering

- Carbon I beams are used in a wide range of applications, from residential and commercial buildings to industrial platforms, bridges, and highway construction. Their versatility stems from the ability to be used both as structural support elements, such as beams and columns, and as architectural features.

3. Cost-Effectiveness

- The efficient shape of I beams, maximizing the distribution of material where it provides the most strength, makes them a cost-effective choice for many projects. They require less steel to achieve the same structural performance as other shapes, which can lead to cost savings in materials and foundation support.

4. Durability and Maintenance

- Carbon steel I beams exhibit excellent durability and resistance to wear and tear, making them suitable for long-term use in construction projects. While they do require protection against corrosion (often achieved through painting or galvanization), their overall maintenance requirements are relatively low compared to other structural materials.

5. Ease of Installation

- I beams can be easily fabricated, cut, and welded to meet specific project requirements, making the construction process more straightforward. Their standard shapes and sizes also contribute to easier handling and faster installation on-site, reducing construction times and labor costs.

6. Sustainability

- Steel is highly recyclable, and carbon I beams can be repurposed or recycled at the end of their lifecycle, contributing to sustainable construction practices. The use of steel beams in construction also aligns with modern building standards that emphasize energy efficiency and environmental responsibility.

In summary, carbon I beam steel is a fundamental component in the construction and engineering sectors due to its strength, versatility, cost-effectiveness, durability, ease of installation, and sustainability. These characteristics make it an indispensable material for building the backbone of modern infrastructure.

Profile package and shipment

Carbon steel profile video

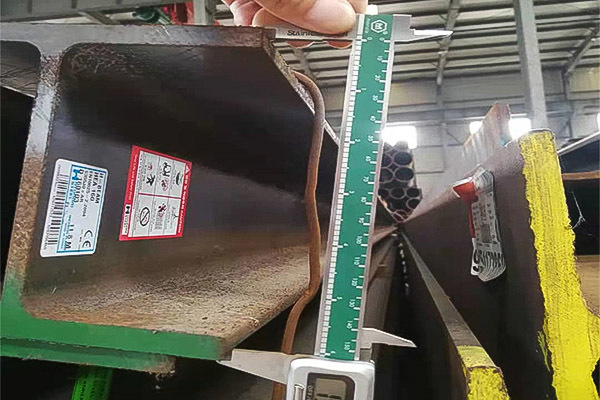

Carbon steel profile inspection

Produce-shipment-service

Modern factory

Professional production

single customize

plenty stockhouse

Delivery ontime

shipping support

prepare inspection

Global servise

Related products

FAQ

A What range of steel products does your factory produce?

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

B Are your steel products certified or graded, and how can I trust their quality?

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

CCan your factory handle bulk orders within short time frames?

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

D How does your company ensure the sustainability of production?

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

E What measures are in place to ensure the safety and welfare of workers in your factory?

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

F Do you offer customized steel solutions for specific industry needs?

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

G How do you handle logistics and transportation, and can customers track their orders?

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

H What is your policy on returns or defective products?

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.